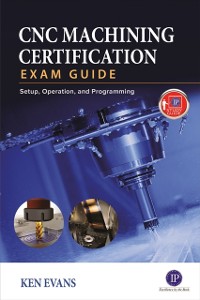

CNC Machining Certification Exam Guide

Ken Evans

Naturwissenschaften, Medizin, Informatik, Technik / Technik

Beschreibung

CNC Machining Certification Exam Guide is focused on providing the knowledge base required for obtaining certification, credentialing and/or job preparation in CNC Machining with CNC Mills and Lathes. It covers foundational skills that all those seeking employment as a CNC Operator/Machinist must possess. Managers responsible for workforce development in manufacturing facilities will use the book as a guide for on-the-job employee training and apprenticeships.

The work can be used as a curriculum component for technical schools and colleges for students preparing for certification and credentialing exams based on the National Institute for Metalworking Skills (NIMS) Machining Level I standards for: CNC Mill Programming and Setup and Operations, and CNC Lathe Programming and Setup and Operations. At a time when the CNC market is experiencing a shortfall of skilled, qualified workers, this Exam Guide is the perfect resource

Features

- Presents CNC Programming with G-Code so users can execute their programs with confidence.

- Focuses on the creation of CNC programs using Computer Aided Manufacturing (CAM).

- Written with the end goals of certification, credentialing and job readiness in mind.

- Practice study questions mimic those presented on credentialing exams and practice exercises prepare readers for the required practical activities.

- An affiliated website (www.CNCCertification.com) will contain additional certification questions and answers, as well as suggested additional exercises.

Kundenbewertungen

CNC machining, safety, maintenance, cutting tools, calculations, tool assembly, GD&T, geometric dimensioning and tolerancing, deburring, inspection, surface finish, programming, G-codes, M-codes, tool offsets, radius, nose compensation, operation, setup, fixture alignment, work holding, milling, JOG, MDI, offsets, program proofing, program dry run, automatic cycle, single block, program editing, lathes, coordinate system, turning, part program zero, display screens, CAM software functions, tool path generat